- Servo Drive

- Stainless Steel Construction

- Rotatory Motion Sealing Jaws for Horizontal Sealing and Cutting

- High precision photo eye detection

- PLC with 7” colored HMI

- Hygienic Design for Easy Cleaning

- Driven Reel Holder

- Fast change overs

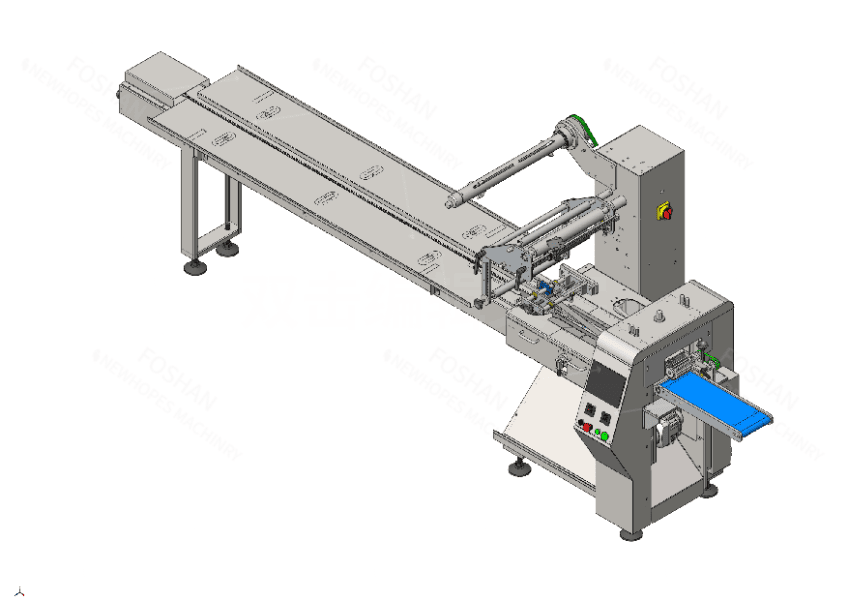

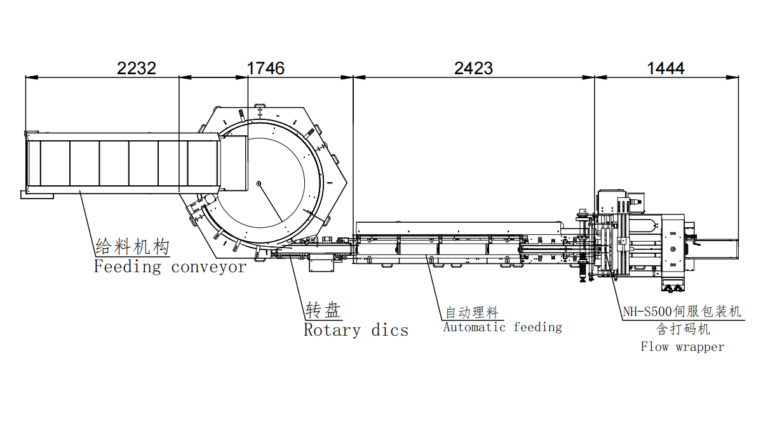

flow pack machine

Our fully automatic flowpack machines can handle a range of applications depending on the variant. They are capable of high-speed packaging and sealing for both film and paper materials, with the option to choose between vertical sealing from above or below.

The machines come equipped with rotating or reciprocating sealing units and can be combined with various types of feeds such as finger transport chains or infeed conveyors. Whether it’s PP, aluminum composite foils, or coated paper, we have the solutions.