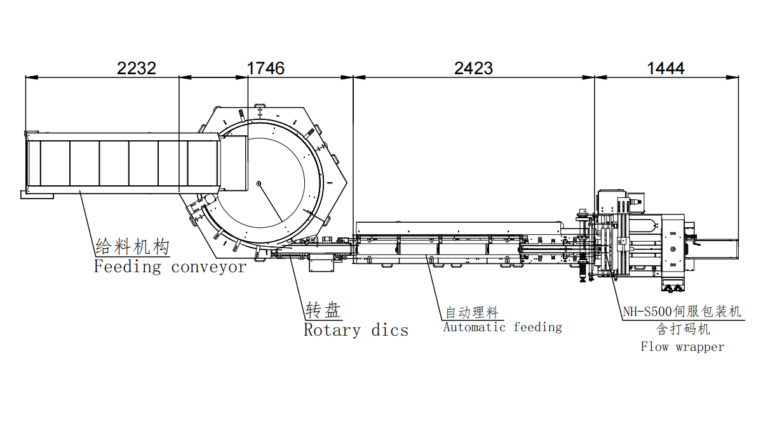

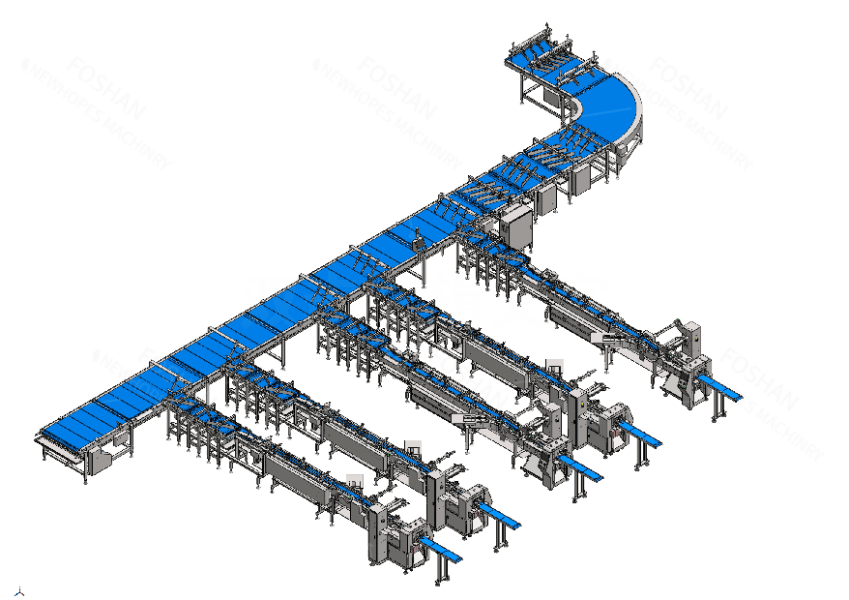

- Row distribution system

- Servo Drive

- Stainless Steel Construction

- Toolless belt changeover

- Adjustable belt speed to coordinate with production line capacity

Previous

Next

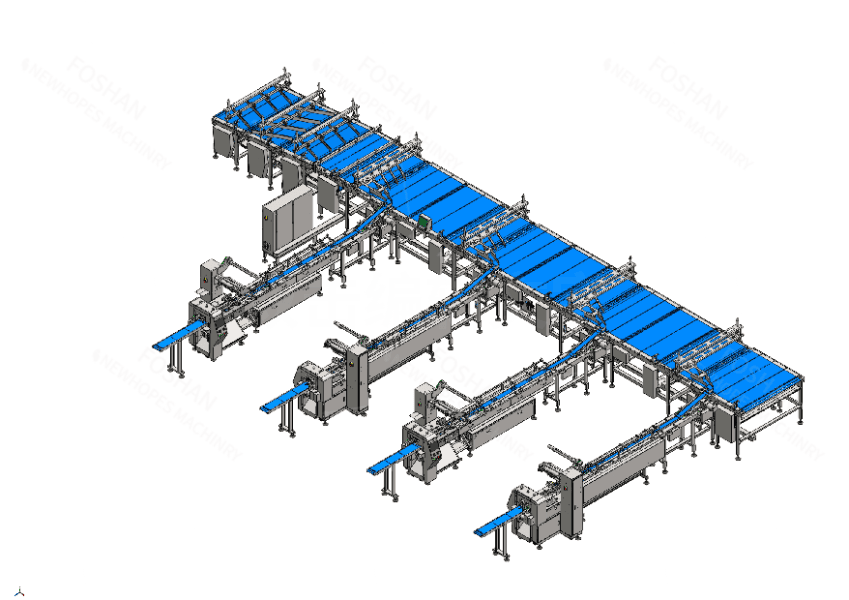

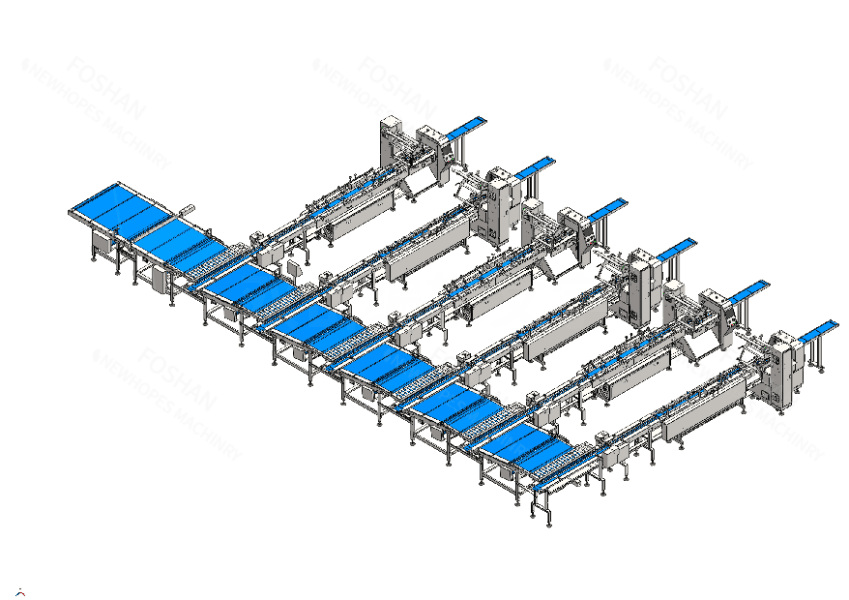

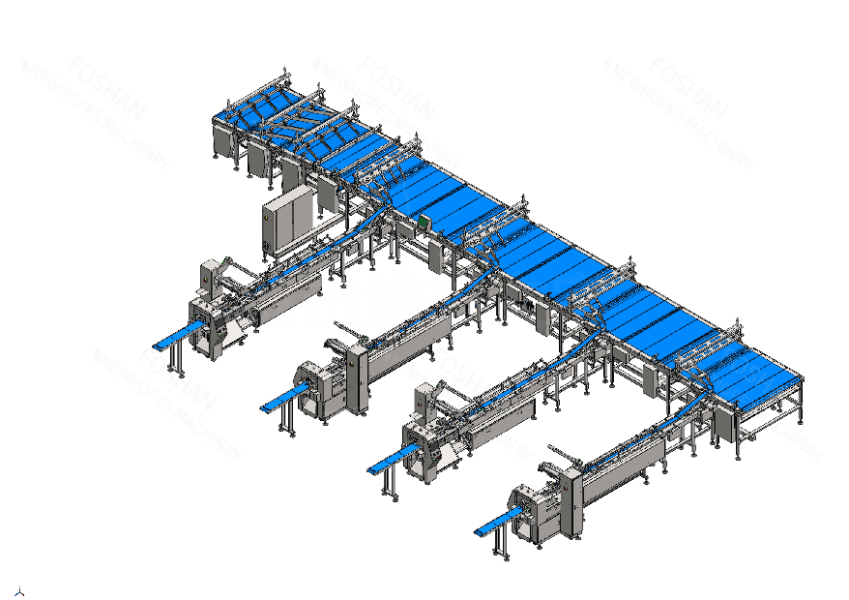

Infeed System

The automatic feeding system is an important part of the food automation packaging system. Designing the optimal feeding system according to the different product characteristics can greatly improve production efficiency.

An optimal feeding system can also enhance the quality and consistency of the packaged products.

Newhopes manufacture the cross feeder, alignment feeder, disk turntable feeder for various products to get you covered in food packaging.