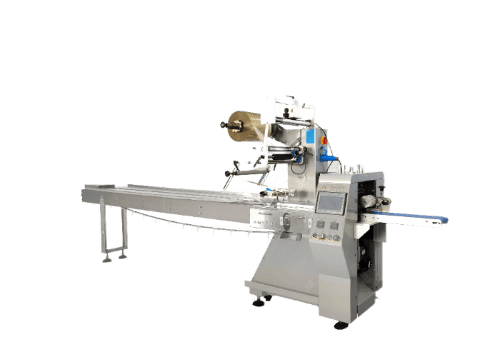

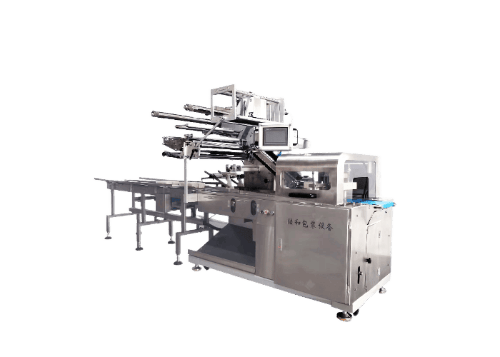

Flow pack equipment is a versatile packaging machine that wraps product in a film-formed bag.

It is widely used in the food industry but has applications in other sectors, such as pharmaceuticals, cosmetics, and household products. The flow pack process is also known as horizontal form-fill-seal (HFFS) packaging.

Factors Impacting the Price of Flow Pack Equipment

The price of flow pack equipment can vary based on several factors, including:

- Model: Different models of flow pack equipment have varying features and capabilities, which can impact their price.

- Configuration: The configuration of the equipment can also affect the price. Some models may come with additional functions or options that increase the cost.

- Manufacturer Brand: With well-known brands often command a higher price point.

Common Applications of Flow Pack Equipment in Various Industries

Flow pack equipment is commonly used in various industries, including:

- Bakery: Flow pack machines pack bread, buns, pastries, and cakes in a sealed package to maintain freshness and increase shelf life.

- Biscuit: Flow pack equipment packs biscuits to preserve their taste and texture.

- Bread: Flow pack equipment packs sliced bread in a sealed package to keep it fresh.

- Candy: Flow pack equipment packs individual pieces of candy in a sealed package, which can be displayed on store shelves.

Types of Flow Pack Equipment and Their Features

There are two main types of flow pack equipment:

- Rotary Sealing Jaw: This type of flow pack equipment uses a rotary motion to seal the packaging material around the product. It is commonly used for higher-speed and small package applications.

- Reciprocating Sealing Jaw (Box Motion): This type of flow pack equipment uses a reciprocating motion to seal the packaging material around the product. It is commonly used for more airtight sealed applications.

Key Considerations When Selecting Flow Pack Equipment for Your Business

When selecting flow pack equipment for your business, there are several key considerations to keep in mind:

- Product Characteristics: The characteristics of your product, such as its shape, size, and weight, will impact the type and model of flow pack equipment needed.

- Packaging Dimensions: The dimensions of the packaging material and the finished package will determine the size of the flow pack machine required.

- Packaging Capacity: Calculate your daily maximum required packaging capacity and future expansion.

- Factory Space Availability: The available space in your factory or production facility will decide the proposed system layout.

- Budget: Your budget will also impact the type of flow pack equipment you can afford.

Evaluating the Total Cost of Ownership for Flow Pack Equipment

When evaluating the total cost of ownership for flow pack equipment, there are three main costs to consider:

- Machine Cost: The initial cost of the machine, including any additional configurations or options you may need.

- Usage Cost: The ongoing cost of using the machine, such as electricity, packaging materials, and labor.

- Maintenance Cost: The cost of maintaining the machine, including repairs, spare parts, and regular maintenance.

Top Flow Pack Equipment Manufacturers to Consider for Your Business

There are several flow pack equipment manufacturers to consider when selecting a machine for your business, including:

- Ilapak

- Bosch

- Fuji

- Ulma

- PFM

- Ossid

- Hayssen

Comparing the Quality and Performance of Flow Pack Equipment from Different Suppliers

When comparing the quality and performance of flow pack equipment from different suppliers, consider the following factors:

- Reliability: Look for suppliers with a proven track record of producing reliable equipment, using high-quality components and materials, and having positive online reviews and referrals.

- Speed: Choose equipment that can meet your required speed without compromising quality. Ensure the supplier offers a suitable machine speed at a reliable running status and produces nicely sealed packaging.

- Ease of operation: Select a supplier that offers accessible equipment to set up, operate, and maintain and provides training and support to ensure maximum efficiency.

- Durability: Evaluate the type of materials and construction the supplier uses to ensure long-lasting equipment with reliable performance over time.

- Customer support and after-sales service: Choose a supplier that offers comprehensive support, including installation, training, and ongoing maintenance, to get the most out of your investment and ensure smooth and efficient operations.

Overall, comparing the quality and performance of flow pack equipment from different suppliers requires careful consideration of these factors. You can select a supplier that offers the right equipment to meet your specific needs by evaluating each.

Negotiating Pricing and Payment Terms with Flow Pack Equipment Manufacturers

Negotiating pricing and payment terms with manufacturers is an important step when purchasing flow pack equipment. There are some critical factors to consider when dealing with suppliers:

- Research: Before you begin negotiations, research the typical pricing range for the needed equipment. This can help you set reasonable expectations and avoid overpaying. You can also explore the supplier’s reputation to determine if their equipment is worth the investment.

- Quantity: If you plan to purchase multiple machines or a large volume of equipment, you can negotiate a lower price per unit. Be sure to communicate your needs and negotiate accordingly.

- Customization: If you require customized features or modifications to the equipment, this can impact the price. Discuss your needs with the supplier and negotiate a fair price for customizations.

- Payment terms: Consider negotiating payment terms that work for your business, such as a deposit followed by scheduled payments or a financing option. Read the fine print and understand any fees or interest charges associated with financing.

- Maintenance and support: Ask about the supplier’s maintenance and support services and negotiate additional costs or warranties. This can help ensure your equipment stays in good condition and operates efficiently.

- Competitive offers: Consider obtaining offers from multiple suppliers and using these as leverage in negotiations. This can help you negotiate a better price or more favorable terms.

Remember that negotiation is a two-way process. Be open to compromise and be clear about your needs and limitations.

By working with suppliers and negotiating in good faith, you can find a pricing and payment arrangement that works for your business.

Conclusion

In conclusion, purchasing flow pack equipment involves carefully considering several factors, including the type of equipment needed, the application, available space, budget, and supplier reputation.

By understanding these factors and negotiating with suppliers, you can find the right equipment to meet your needs at a competitive price.